While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Automotive and Transportation

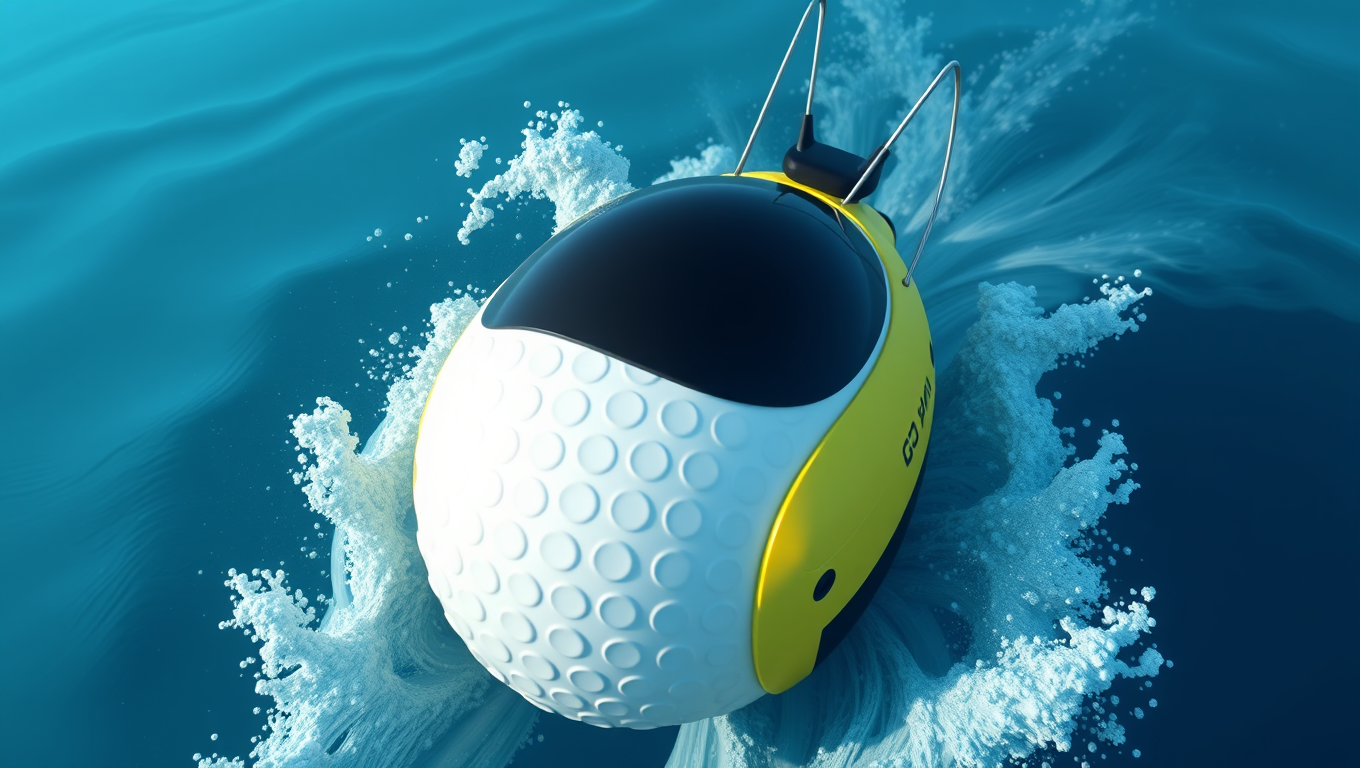

Nimble Dimples: Agile Underwater Vehicles Inspired by Golf Balls

Underwater or aerial vehicles with dimples like golf balls could be more efficient and maneuverable, a new prototype has demonstrated.

Automotive and Transportation

“Revolutionizing Battery Life: Scientists Uncover Secret to Making Aqueous Batteries Last 10x Longer”

A team at KAUST has revealed that the short lifespan of aqueous batteries is primarily due to “free water” molecules triggering harmful chemical reactions at the anode. By adding affordable sulfate salts like zinc sulfate, they significantly reduced this issue—boosting battery life over tenfold. The sulfate acts as a “water glue,” stabilizing the water structure and halting the energy-wasting reactions. Not only is this solution simple and cost-effective, but early results suggest it may be a universal fix for various types of metal-anode aqueous batteries.

Automotive and Transportation

A Breakthrough in Ammonia Production: Harnessing Human-Made Lightning for Sustainable Fertilizers

Australian scientists have discovered a method to produce ammonia—an essential component in fertilizers—using only air and electricity. By mimicking lightning and channeling that energy through a small device, they’ve bypassed the traditional, fossil fuel-heavy method that’s been used for over a century. This breakthrough could lead to cleaner, cheaper fertilizer and even help power the future, offering a potential alternative fuel source for industries like shipping.

Automotive and Transportation

Breakthrough in Green Hydrogen Production: Triple-Layer Catalyst Supercharges Energy Yield by 800%

Researchers in Sweden have developed a powerful new material that dramatically boosts the ability to create hydrogen fuel from water using sunlight, making the process eight times more effective than before. This breakthrough could be key to fueling heavy transport like ships and planes with clean, renewable energy.

-

Detectors9 months ago

Detectors9 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate11 months ago

Earth & Climate11 months agoRetiring Abroad Can Be Lonely Business

-

Cancer10 months ago

Cancer10 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Albert Einstein11 months ago

Albert Einstein11 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry10 months ago

Chemistry10 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate10 months ago

Earth & Climate10 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals

-

Agriculture and Food10 months ago

Agriculture and Food10 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions11 months ago

Diseases and Conditions11 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention