While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Civil Engineering

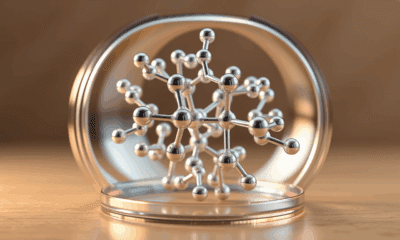

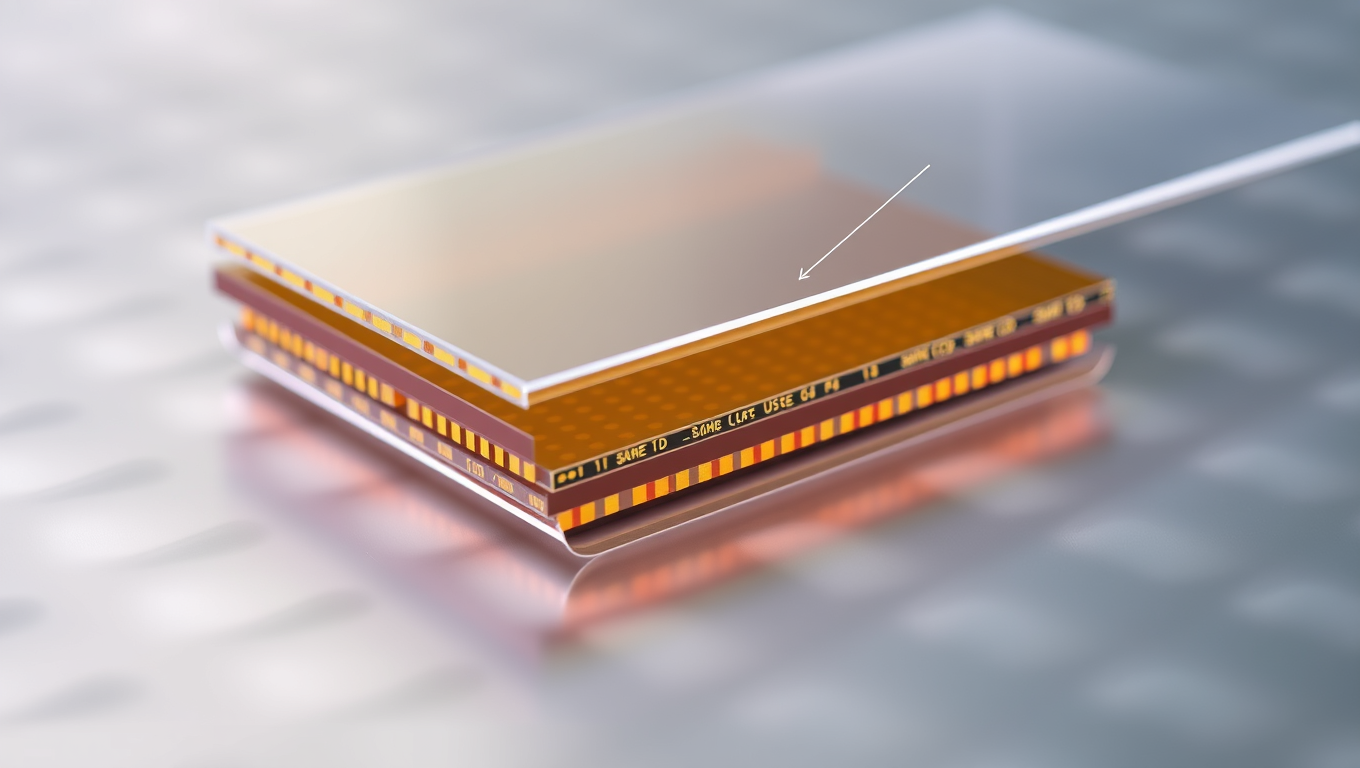

A Breakthrough in Self-Healing Materials: A Multilayered Film with Superior Hardness and Thermal Stability

Self-healing coatings are advanced materials that can repair damage, such as scratches and cracks on their own. Researchers have developed an efficient method for preparing self-healing films consisting of alternating layers of highly cross-linked organosiloxane and linear polydimethylsiloxane (PDMS). Their film is more durable than conventional self-healing PDMS materials, offering superior hardness and greater thermal stability while self-healing at mild temperatures, paving the way for stronger, more reliable, and easier-maintained self-healing materials.

Chemistry

“Harnessing Defects: A New Mathematical Framework for Strengthening Materials”

Crystals may seem flawless, but deep inside they contain tiny structural imperfections that dramatically influence their strength and behavior. Researchers from The University of Osaka have used the sophisticated math of differential geometry to reveal how these defects—like dislocations and disclinations—interact in elegant, unified ways. Their findings could help scientists engineer tougher, smarter materials by intentionally leveraging these flaws rather than avoiding them.

Biochemistry

A Game-Changing mRNA Vaccine that’s More Effective and Less Costly to Develop

A new type of mRNA vaccine is more scalable and adaptable to continuously evolving viruses such as SARS-CoV-2 and H5N1, according to a new study.

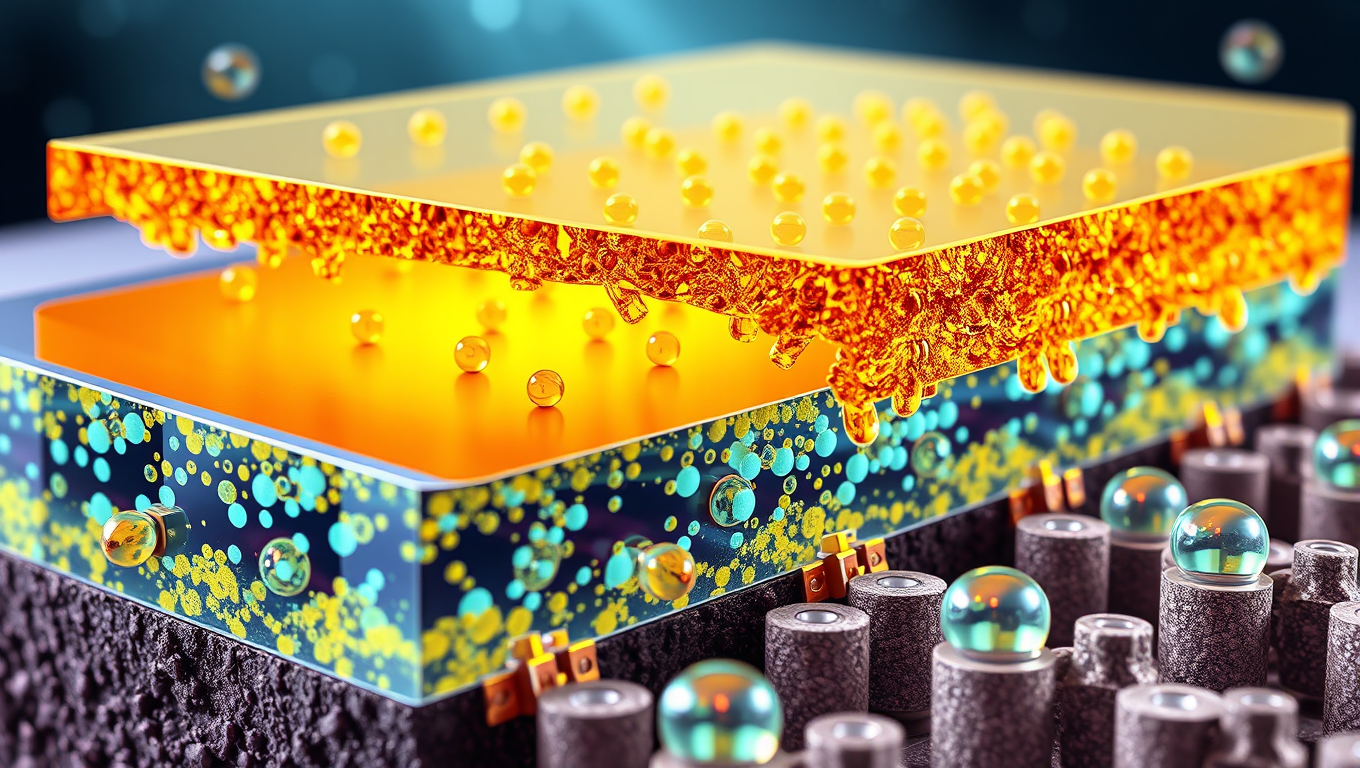

Batteries

Unlocking the Potential of Solid-State Batteries

Researchers have discovered that the mixing of small particles between two solid electrolytes can generate an effect called a ‘space charge layer,’ an accumulation of electric charge at the interface between the two materials. The finding could aid the development of batteries with solid electrolytes, called solid-state batteries, for applications including mobile devices and electric vehicles.

-

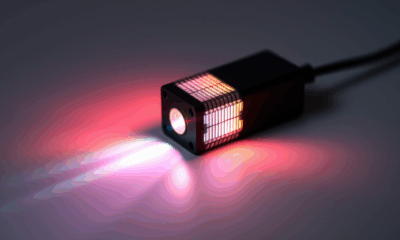

Detectors3 months ago

Detectors3 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate4 months ago

Earth & Climate4 months agoRetiring Abroad Can Be Lonely Business

-

Cancer4 months ago

Cancer4 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Agriculture and Food4 months ago

Agriculture and Food4 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions4 months ago

Diseases and Conditions4 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention

-

Albert Einstein4 months ago

Albert Einstein4 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry4 months ago

Chemistry4 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate4 months ago

Earth & Climate4 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals