While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Earth & Climate

A Breakthrough in Termite Control: A Targeted Terminator for Drywood Termites

Researchers have identified a chemical that kills about 95 percent of a western drywood termite colony without off-target effects on mammals.

Air Quality

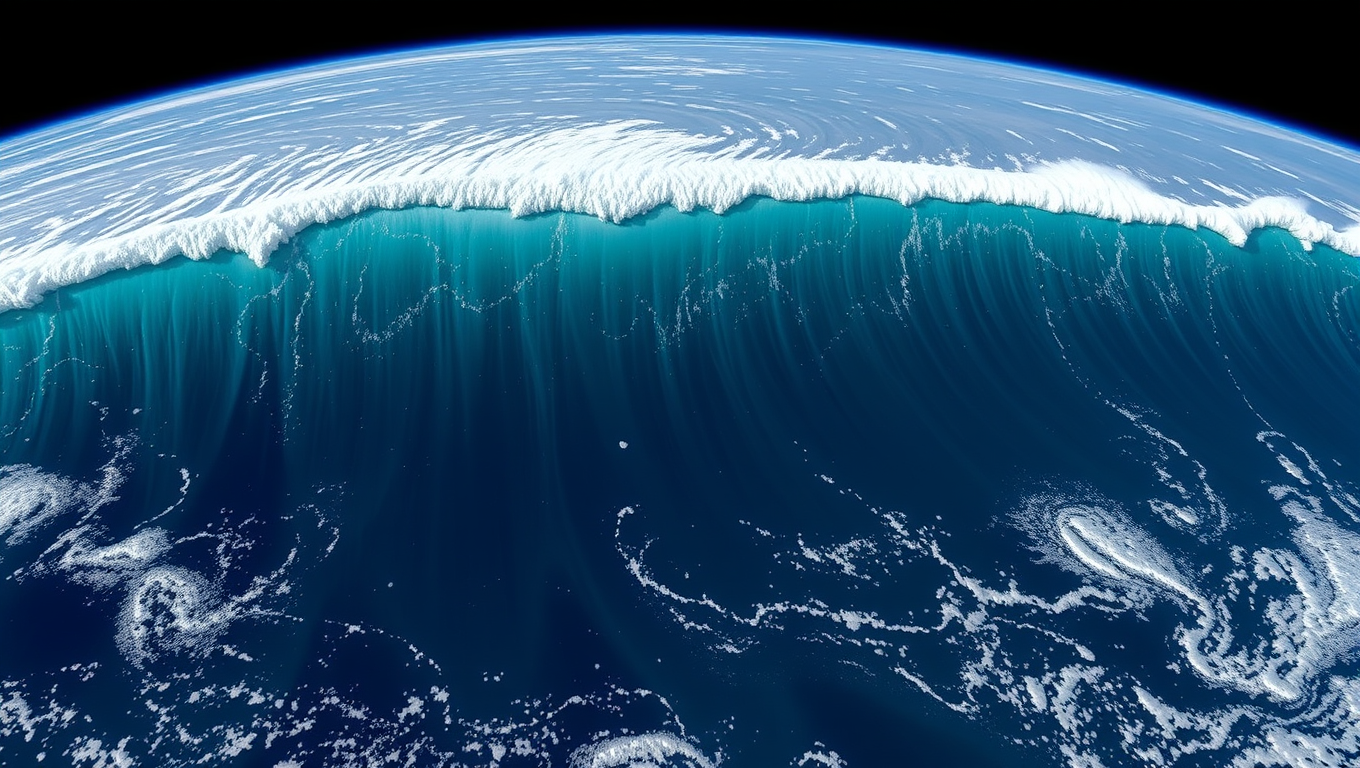

Greenland’s Glacial Runoff Fuels Explosive Growth in Ocean Life

NASA-backed simulations reveal that meltwater from Greenland’s Jakobshavn Glacier lifts deep-ocean nutrients to the surface, sparking large summer blooms of phytoplankton that feed the Arctic food web.

Atmosphere

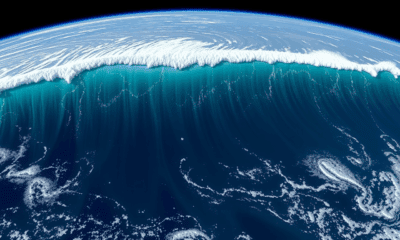

NASA’s SWOT Satellite Captures Kamchatka Megaquake Tsunami in Stunning Detail

When a massive 8.8 magnitude earthquake struck off Russia’s Kamchatka Peninsula, NASA and CNES’s SWOT satellite captured a rare and detailed picture of the tsunami that followed. Recorded just over an hour after the quake, the satellite revealed the wave’s height, shape, and path, offering scientists an unprecedented multidimensional view from space.

Climate

The Ocean’s Fragile Fortresses: Uncovering the Impact of Climate Change on Bryozoans

Mediterranean bryozoans, including the “false coral,” are showing alarming changes in structure and microbiomes under acidification and warming. Field studies at volcanic CO₂ vents reveal that these stressors combined sharply reduce survival, posing risks to marine ecosystems.

-

Detectors10 months ago

Detectors10 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate11 months ago

Earth & Climate11 months agoRetiring Abroad Can Be Lonely Business

-

Cancer11 months ago

Cancer11 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Albert Einstein11 months ago

Albert Einstein11 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry10 months ago

Chemistry10 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate11 months ago

Earth & Climate11 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals

-

Agriculture and Food11 months ago

Agriculture and Food11 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions11 months ago

Diseases and Conditions11 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention