While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Electronics

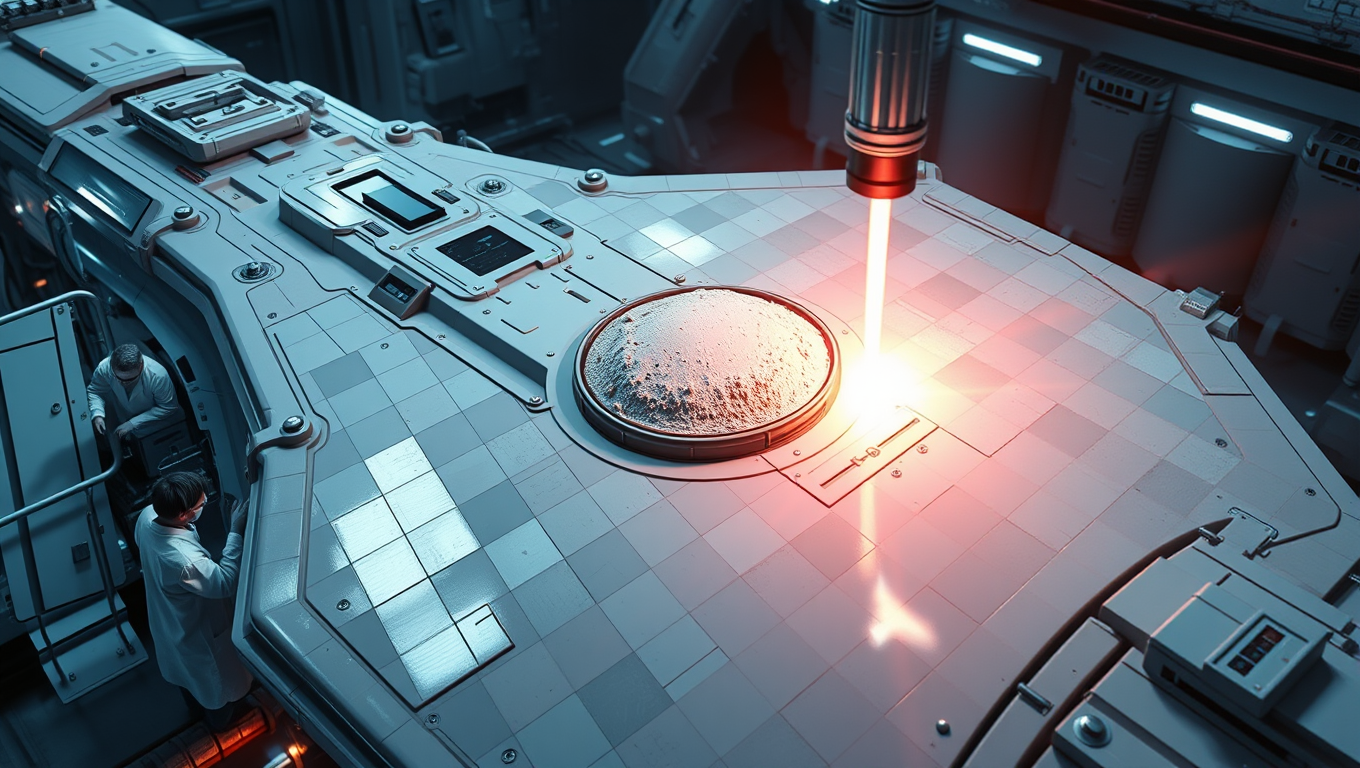

Revolutionizing Ultra-High Temperature Ceramic Manufacturing for Space and Defense Applications

Researchers have demonstrated a new technique that uses lasers to create ceramics that can withstand ultra-high temperatures, with applications ranging from nuclear power technologies to spacecraft and jet exhaust systems. The technique can be used to create ceramic coatings, tiles or complex three-dimensional structures, which allows for increased versatility when engineering new devices and technologies.

Batteries

“Reviving ‘Dead’ Batteries: The Path to a Greener Future”

Lithium battery recycling offers a powerful solution to rising demand, with discarded batteries still holding most of their valuable materials. Compared to mining, recycling slashes emissions and resource use while unlocking major economic potential. Yet infrastructure, policy, and technology hurdles must still be overcome.

Detectors

“Pioneering Electronics for Particle Physics: Columbia’s Breakthroughs at CERN”

Deep beneath the Swiss-French border, the Large Hadron Collider unleashes staggering amounts of energy and radiation—enough to fry most electronics. Enter a team of Columbia engineers, who built ultra-rugged, radiation-resistant chips that now play a pivotal role in capturing data from subatomic particle collisions. These custom-designed ADCs not only survive the hostile environment inside CERN but also help filter and digitize the most critical collision events, enabling physicists to study elusive phenomena like the Higgs boson.

Construction

Scientists Harness Quantum Motion using Ultrafast Laser Trick

Harvard and PSI scientists have managed to freeze normally fleeting quantum states in time, creating a pathway to control them using pure electronic tricks and laser precision.

-

Detectors10 months ago

Detectors10 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate11 months ago

Earth & Climate11 months agoRetiring Abroad Can Be Lonely Business

-

Cancer10 months ago

Cancer10 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Albert Einstein11 months ago

Albert Einstein11 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry10 months ago

Chemistry10 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate10 months ago

Earth & Climate10 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals

-

Agriculture and Food11 months ago

Agriculture and Food11 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions11 months ago

Diseases and Conditions11 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention