While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Detectors

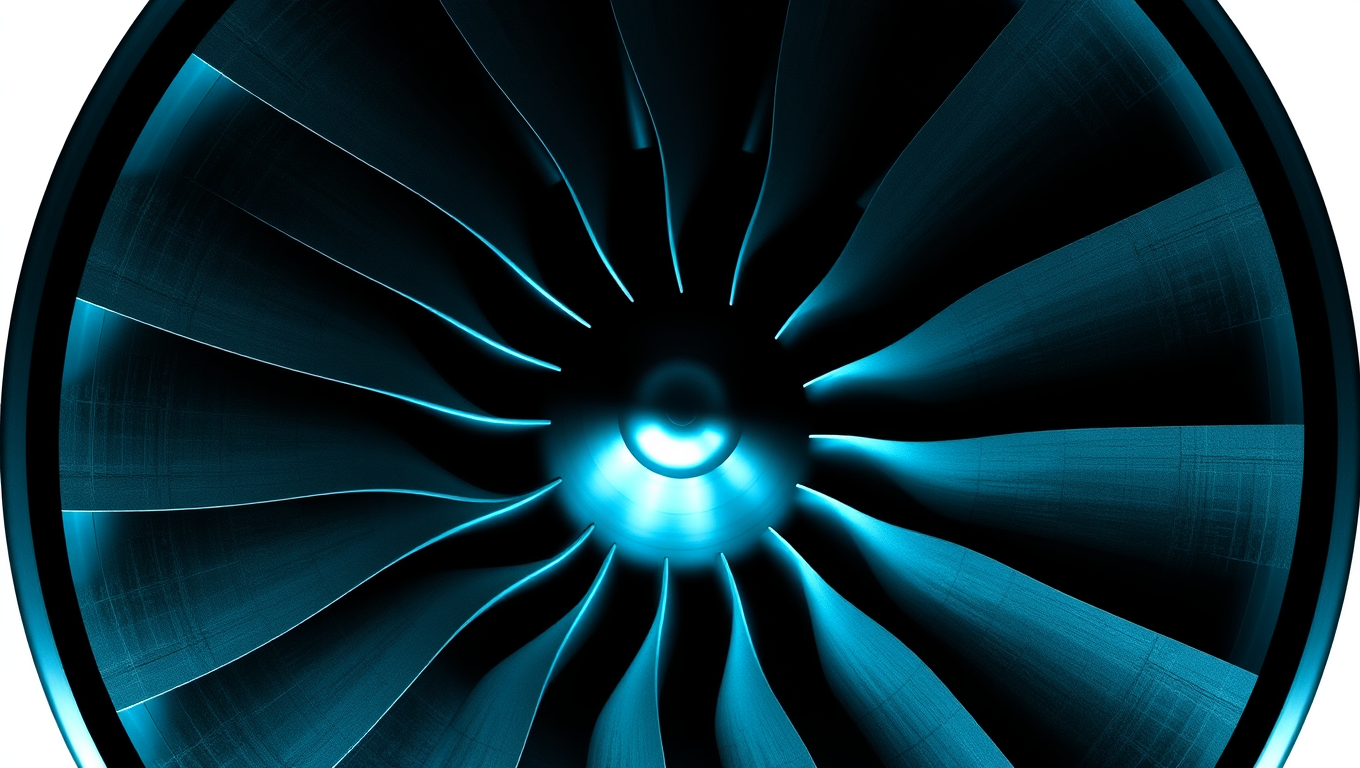

Revolutionizing Industrial Imaging with Laser-Driven CT Scans

A research team has achieved a new milestone in 3D X-ray imaging technology. The scientists have captured high-resolution CT scans of the interior of a large, dense object — a gas turbine blade — using a compact, laser-driven X-ray source. The work is part of a larger vision to leverage high-intensity lasers for a wide range of uses, from studying inertial fusion energy to generating bright beams of GeV electrons and MeV x-rays.

Asteroids, Comets and Meteors

Miniature Marvel: Chip-Scale Laser Revolutionizes Metrology and Beyond

Researchers have engineered a laser device smaller than a penny that they say could power everything from the LiDAR systems used in self-driving vehicles to gravitational wave detection, one of the most delicate experiments in existence to observe and understand our universe.

Detectors

Empowering Communities: Portable Sensor Enables Lead Detection in Tap Water

Lead contamination in municipal water sources is a consistent threat to public health. Ingesting even tiny amounts of lead can harm the human brain and nervous system — especially in young children. To empower people to detect lead contamination in their own homes, a team of researchers developed an accessible, handheld water-testing system called the E-Tongue. This device was tested through a citizen science project across four Massachusetts towns.

Detectors

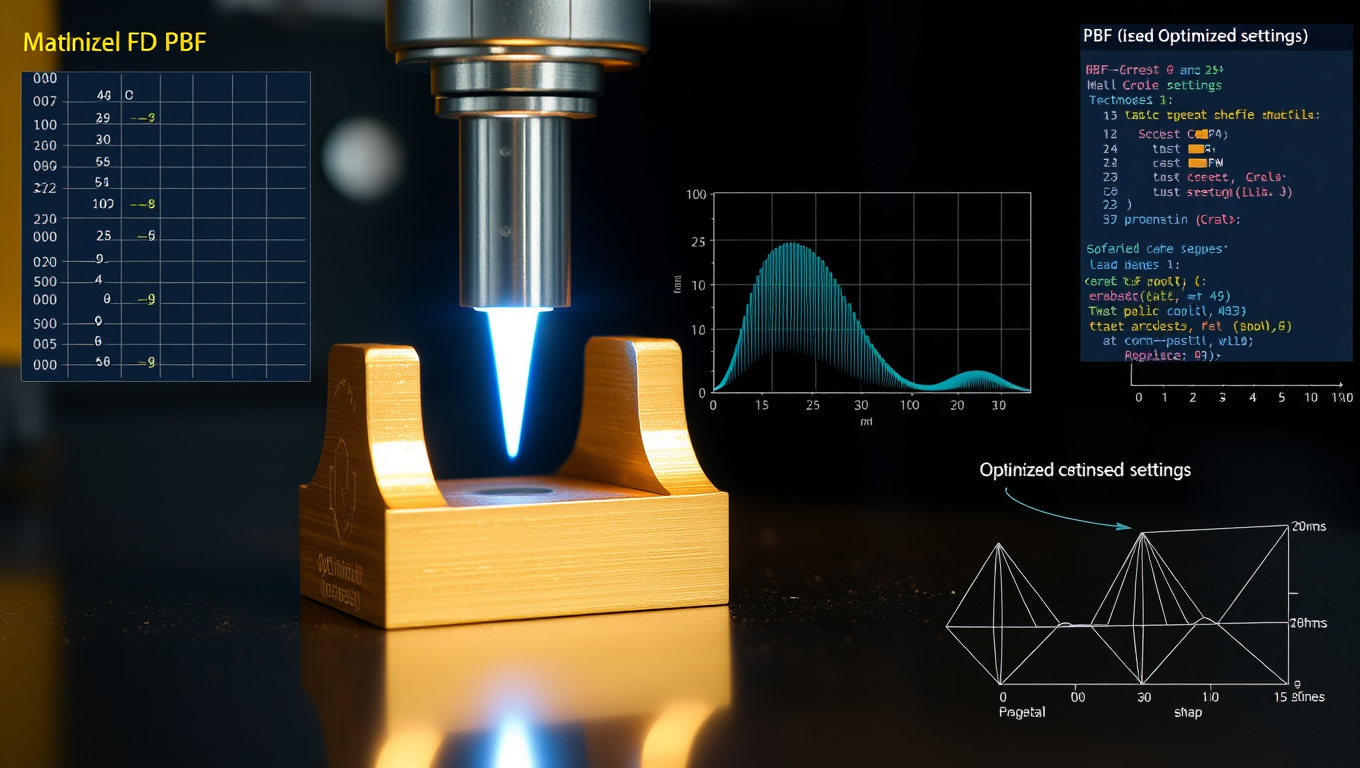

Revolutionizing Industrial Laser Processes with Machine Learning

Laser-based metal processing enables the automated and precise production of complex components, whether for the automotive industry or for medicine. However, conventional methods require time- and resource-consuming preparations. Researchers are now using machine learning to make laser processes more precise, more cost-effective and more efficient.

-

Detectors3 months ago

Detectors3 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate4 months ago

Earth & Climate4 months agoRetiring Abroad Can Be Lonely Business

-

Cancer4 months ago

Cancer4 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Agriculture and Food4 months ago

Agriculture and Food4 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions4 months ago

Diseases and Conditions4 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention

-

Chemistry3 months ago

Chemistry3 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Albert Einstein4 months ago

Albert Einstein4 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Earth & Climate3 months ago

Earth & Climate3 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals