While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Detectors

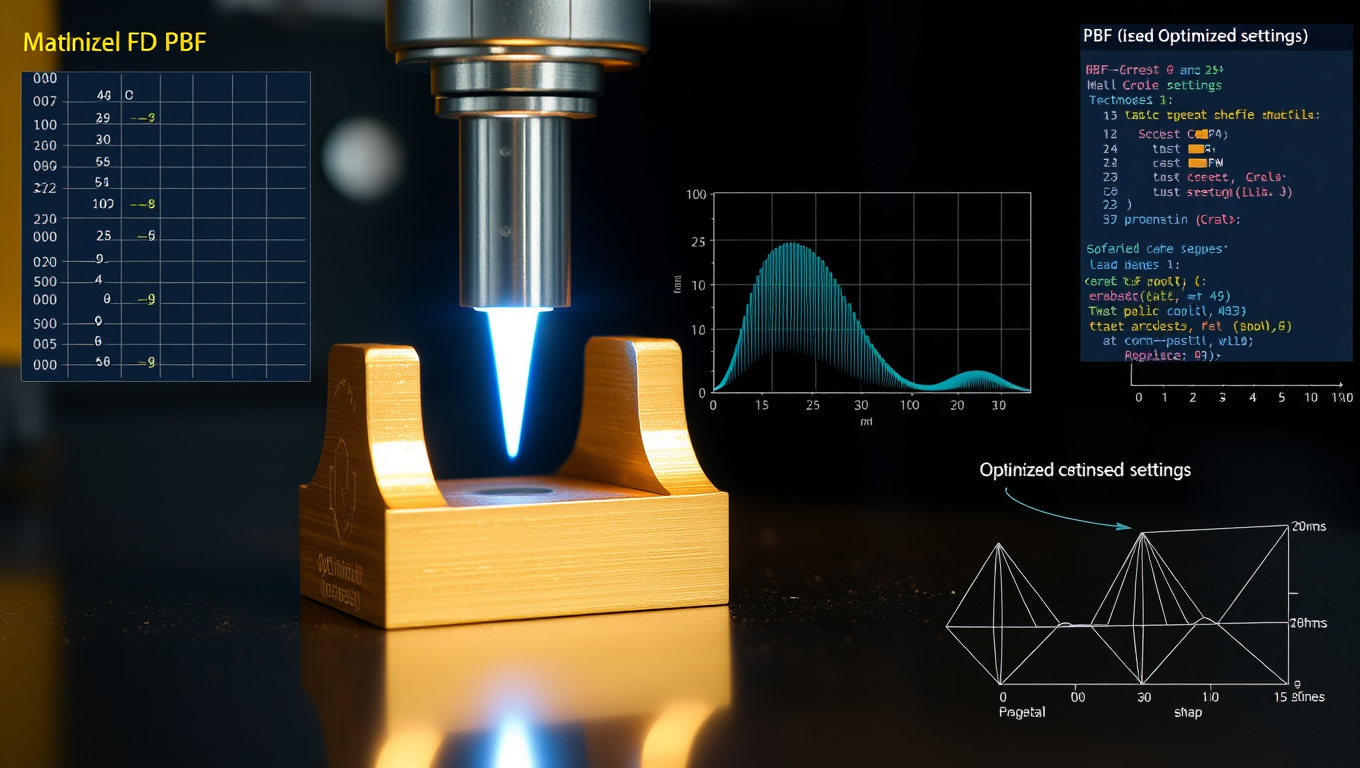

Revolutionizing Industrial Laser Processes with Machine Learning

Laser-based metal processing enables the automated and precise production of complex components, whether for the automotive industry or for medicine. However, conventional methods require time- and resource-consuming preparations. Researchers are now using machine learning to make laser processes more precise, more cost-effective and more efficient.

Chemistry

Scientists Stunned by Record-Breaking, Watermelon-Shaped Nucleus: Breakthrough Discovery in Nuclear Physics

Scientists in Finland have measured the heaviest known nucleus to undergo proton emission, discovering the rare isotope 188-astatine. It exhibits a unique shape and may reveal a new kind of nuclear interaction.

Chemistry

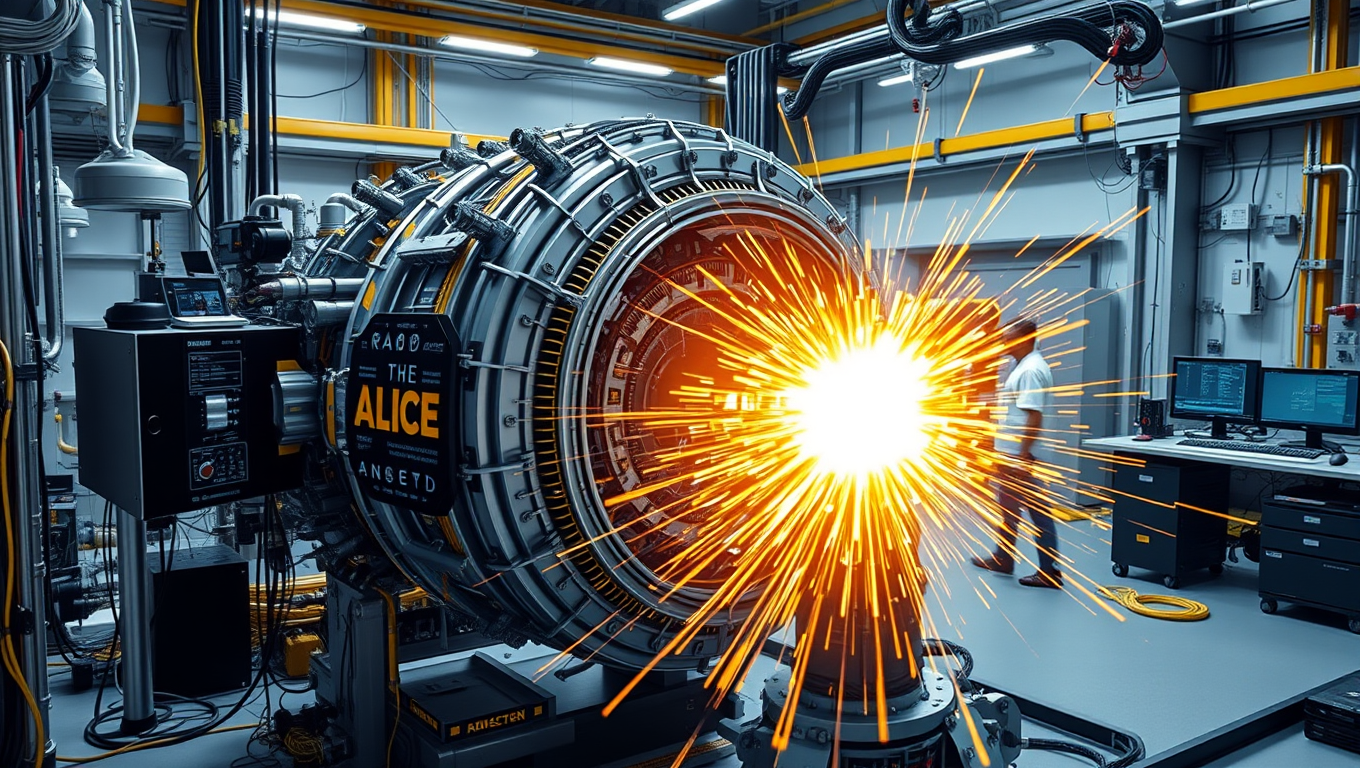

From Lead to Gold in a Fraction of a Second at the Large Hadron Collider

At the Large Hadron Collider, scientists from the University of Kansas achieved a fleeting form of modern-day alchemy — turning lead into gold for just a fraction of a second. Using ultra-peripheral collisions, where ions nearly miss but interact through powerful photon exchanges, they managed to knock protons out of nuclei, creating new, short-lived elements. This breakthrough not only grabbed global attention but could help design safer, more advanced particle accelerators of the future.

Cosmic Rays

The Nuclear Clock That Could Unmask Dark Matter

Physicists are exploring thorium-229’s unique properties to create a nuclear clock so precise it could detect the faintest hints of dark matter. Recent measurement advances may allow scientists to spot tiny shifts in the element’s resonance spectrum, potentially revealing the nature of this mysterious substance.

-

Detectors10 months ago

Detectors10 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate11 months ago

Earth & Climate11 months agoRetiring Abroad Can Be Lonely Business

-

Cancer10 months ago

Cancer10 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Albert Einstein11 months ago

Albert Einstein11 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry10 months ago

Chemistry10 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate10 months ago

Earth & Climate10 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals

-

Agriculture and Food10 months ago

Agriculture and Food10 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions11 months ago

Diseases and Conditions11 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention