While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Batteries

A Safer Way Forward: Developing Miniature Batteries for Research and Testing

Overheating batteries are a serious risk, in the worst cases leading to fires and explosion. A team has now developed a simple, cost-effective method to test the safety of lithium-ion batteries, which opens up opportunities for research into new and safer batteries for the future. The researchers created an intentionally unstable battery which is more sensitive to changes that could cause overheating. The battery is one-fiftieth the size of conventional batteries, so is less resource intensive and tests can be carried out in a smaller lab environment.

Batteries

Nanotech Breakthrough Boosts Solar Cell Efficiency Beyond 10%

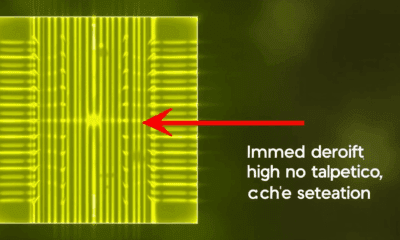

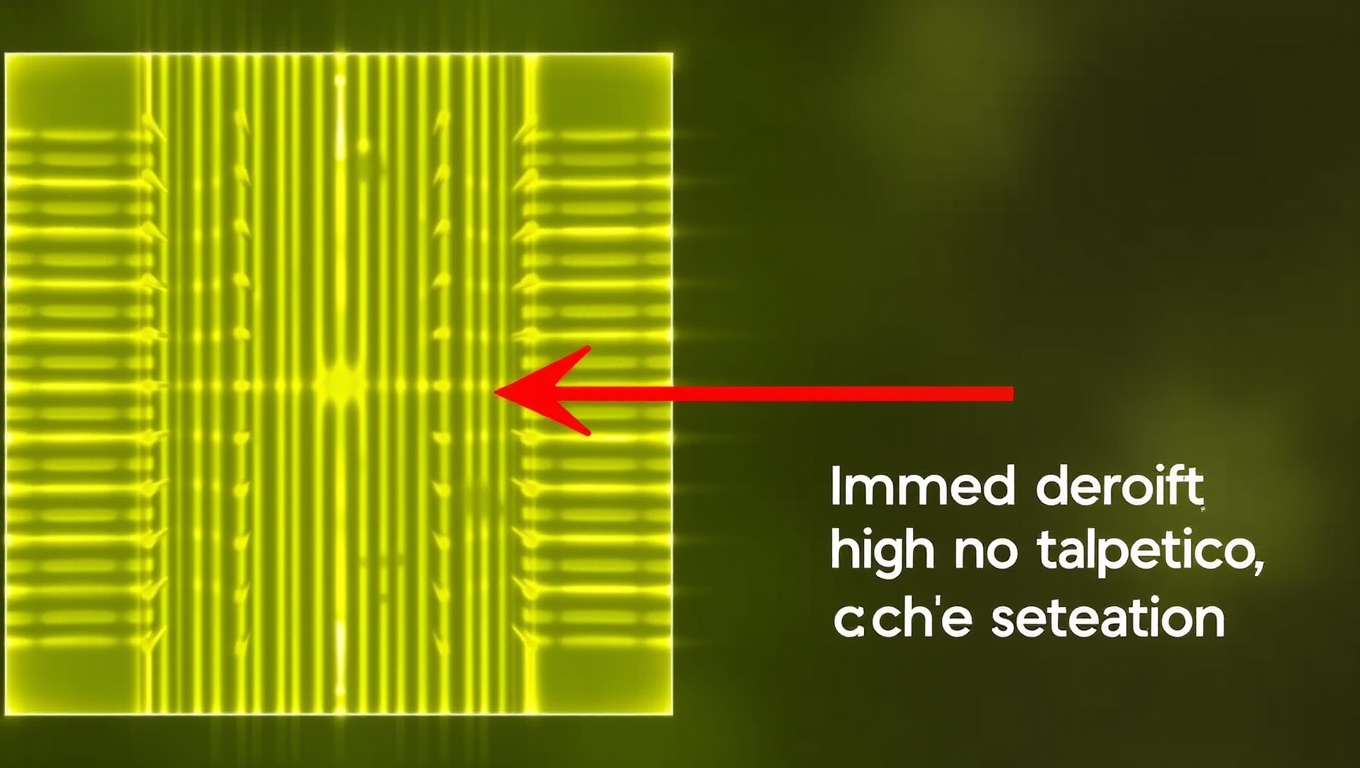

Scientists in China have developed a precise method to grow titanium dioxide nanorod arrays with controllable spacing, independent of rod size. This innovation boosts solar cell efficiency by allowing light capture and charge movement to be fine-tuned.

Automotive and Transportation

Breakthrough in Green Hydrogen Production: Triple-Layer Catalyst Supercharges Energy Yield by 800%

Researchers in Sweden have developed a powerful new material that dramatically boosts the ability to create hydrogen fuel from water using sunlight, making the process eight times more effective than before. This breakthrough could be key to fueling heavy transport like ships and planes with clean, renewable energy.

Batteries

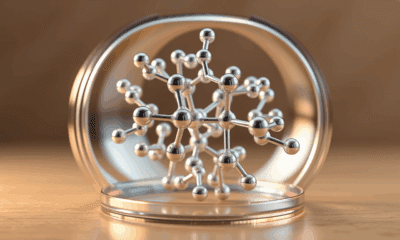

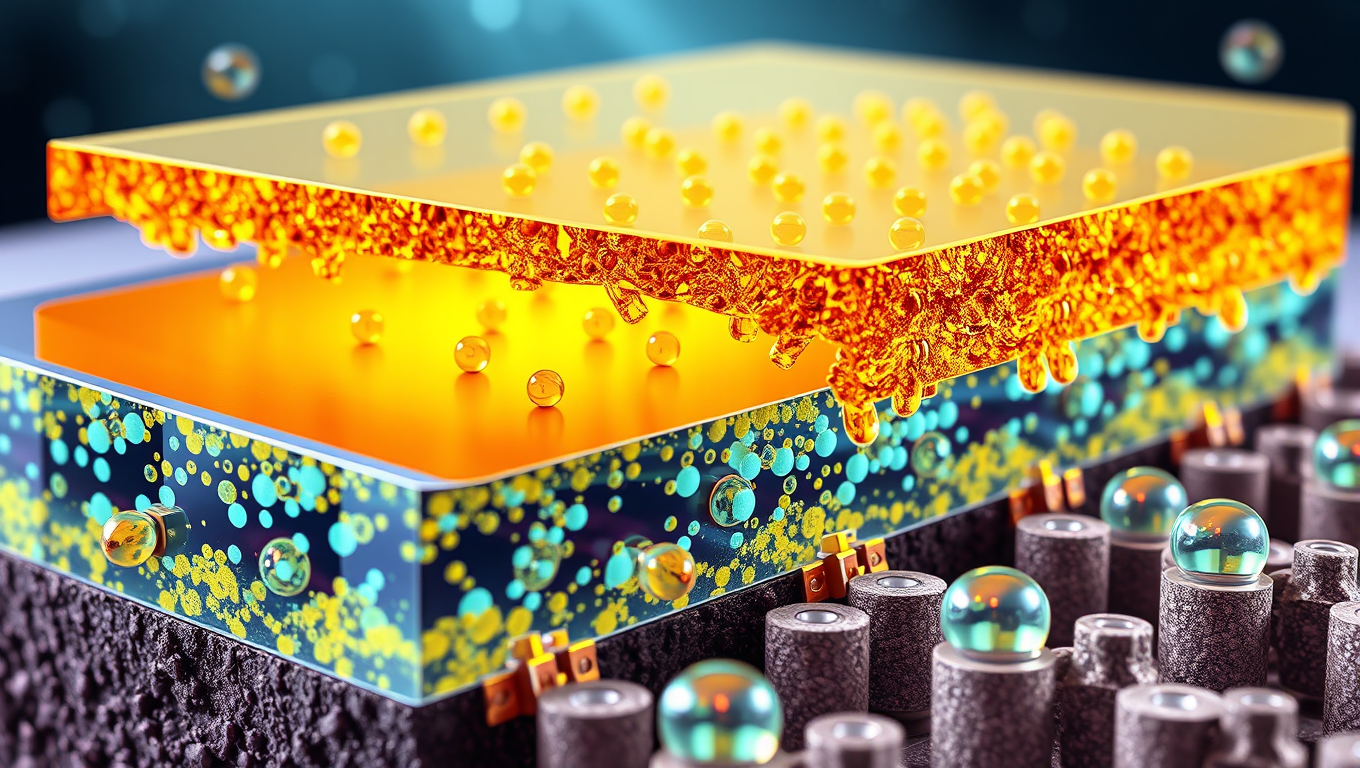

Unlocking the Potential of Solid-State Batteries

Researchers have discovered that the mixing of small particles between two solid electrolytes can generate an effect called a ‘space charge layer,’ an accumulation of electric charge at the interface between the two materials. The finding could aid the development of batteries with solid electrolytes, called solid-state batteries, for applications including mobile devices and electric vehicles.

-

Detectors3 months ago

Detectors3 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate4 months ago

Earth & Climate4 months agoRetiring Abroad Can Be Lonely Business

-

Cancer4 months ago

Cancer4 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Agriculture and Food4 months ago

Agriculture and Food4 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions4 months ago

Diseases and Conditions4 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention

-

Albert Einstein4 months ago

Albert Einstein4 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry4 months ago

Chemistry4 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate4 months ago

Earth & Climate4 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals