While we try to keep things accurate, this content is part of an ongoing experiment and may not always be reliable.

Please double-check important details — we’re not responsible for how the information is used.

Artificial Intelligence

“The Future Brew: Coffee-Making Robot Paves Way for Next-Gen Intelligent Machines”

An AI-powered robot that can prepare cups of coffee in a busy kitchen could usher in the next generation of intelligent machines, a study suggests.

Artificial Intelligence

Scientists Uncover the Secret to AI’s Language Understanding: A Phase Transition in Neural Networks

Neural networks first treat sentences like puzzles solved by word order, but once they read enough, a tipping point sends them diving into word meaning instead—an abrupt “phase transition” reminiscent of water flashing into steam. By revealing this hidden switch, researchers open a window into how transformer models such as ChatGPT grow smarter and hint at new ways to make them leaner, safer, and more predictable.

Artificial Intelligence

The Quantum Drumhead Revolution: A Breakthrough in Signal Transmission with Near-Perfect Efficiency

Researchers have developed an ultra-thin drumhead-like membrane that lets sound signals, or phonons, travel through it with astonishingly low loss, better than even electronic circuits. These near-lossless vibrations open the door to new ways of transferring information in systems like quantum computers or ultra-sensitive biological sensors.

Artificial Intelligence

AI Uncovers Hidden Heart Risks in CT Scans: A Game-Changer for Cardiovascular Care

What if your old chest scans—taken years ago for something unrelated—held a secret warning about your heart? A new AI tool called AI-CAC, developed by Mass General Brigham and the VA, can now comb through routine CT scans to detect hidden signs of heart disease before symptoms strike.

-

Detectors3 months ago

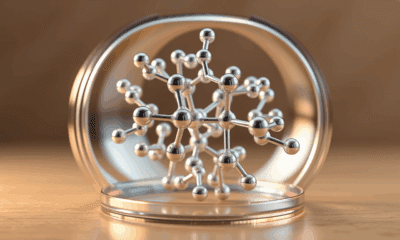

Detectors3 months agoA New Horizon for Vision: How Gold Nanoparticles May Restore People’s Sight

-

Earth & Climate4 months ago

Earth & Climate4 months agoRetiring Abroad Can Be Lonely Business

-

Cancer4 months ago

Cancer4 months agoRevolutionizing Quantum Communication: Direct Connections Between Multiple Processors

-

Agriculture and Food4 months ago

Agriculture and Food4 months ago“A Sustainable Solution: Researchers Create Hybrid Cheese with 25% Pea Protein”

-

Diseases and Conditions4 months ago

Diseases and Conditions4 months agoReducing Falls Among Elderly Women with Polypharmacy through Exercise Intervention

-

Albert Einstein4 months ago

Albert Einstein4 months agoHarnessing Water Waves: A Breakthrough in Controlling Floating Objects

-

Chemistry4 months ago

Chemistry4 months ago“Unveiling Hidden Patterns: A New Twist on Interference Phenomena”

-

Earth & Climate4 months ago

Earth & Climate4 months agoHousehold Electricity Three Times More Expensive Than Upcoming ‘Eco-Friendly’ Aviation E-Fuels, Study Reveals